What type of equipment is used to create blister packages?

Packaging machinery is one of the vital equipment in the pharmaceutical industry, food processing, and chemical industries among which blister packaging machines are widely used for packaging capsules, pills, tablets, suppositories, etc. We can get an effective and safe packaging of tablets from a tablet press or capsules from capsule filling with the help of a blister packing machine. The blister packing machine is designed for packing the different products (tablets, the strong or delicate gelatin capsules, and so forth) into a blister.

In this guide, you will get to know everything about the blister packaging equipment, from the uses, benefits, disadvantages, etc.

Types of Blister Packaging Machines

Depending on the working principle and structure, you can select three types of blister packaging machines including:

Roller Blister Packaging Machine

Flat Forming Blister Packing Machine

Roller Plate Blister Packaging Machine

Methods of operation of blister packing machines

To complete the blister packaging process, there are three methods -

Hand operation

Semi-automatic operation

Automatic operation

The following are our automated production machines.

So what are the steps for using machines to make blister packaging?

First Step:

Customers present a product to be packaged (or submit a drawing of the design) or we can design for you based on your needs.

Second Step:

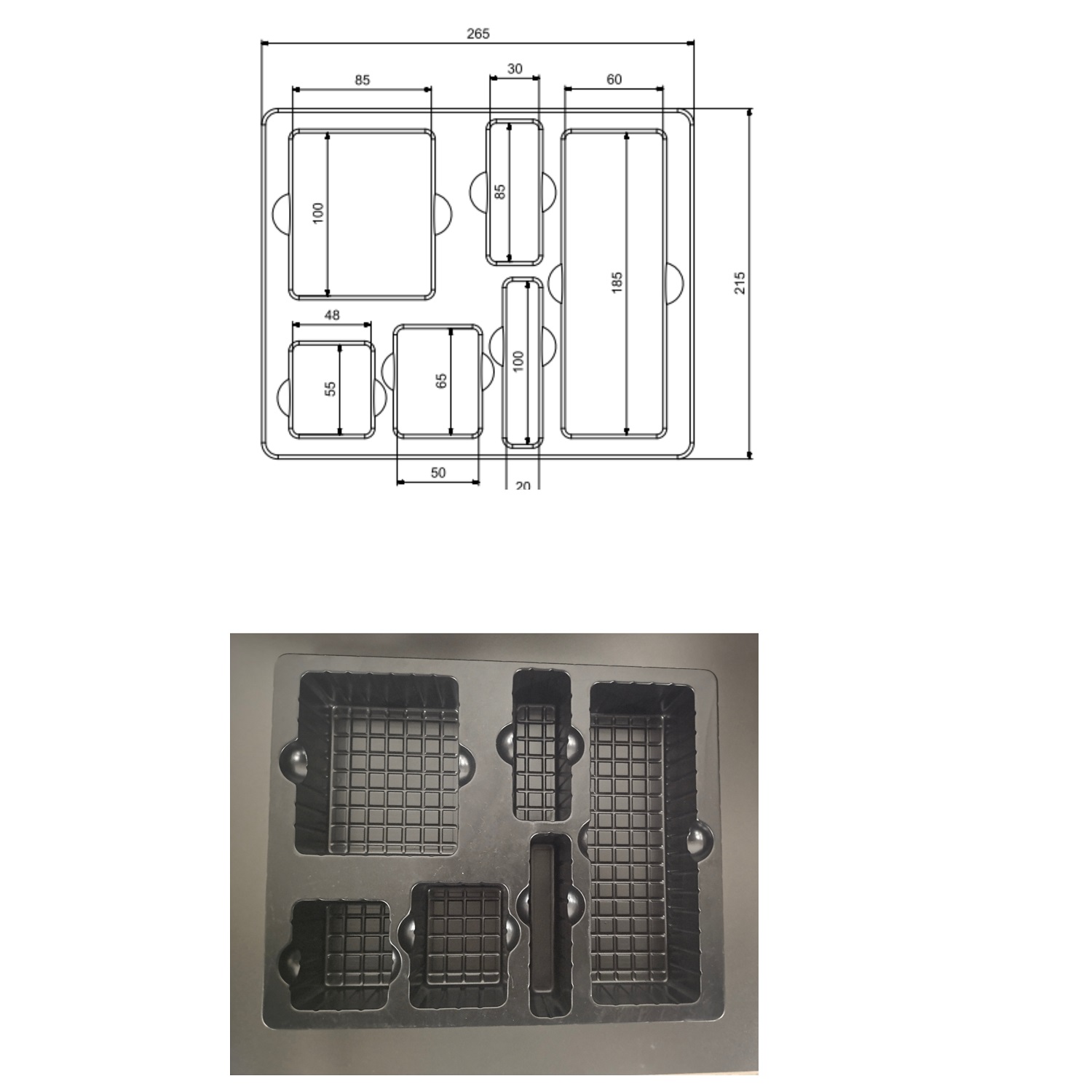

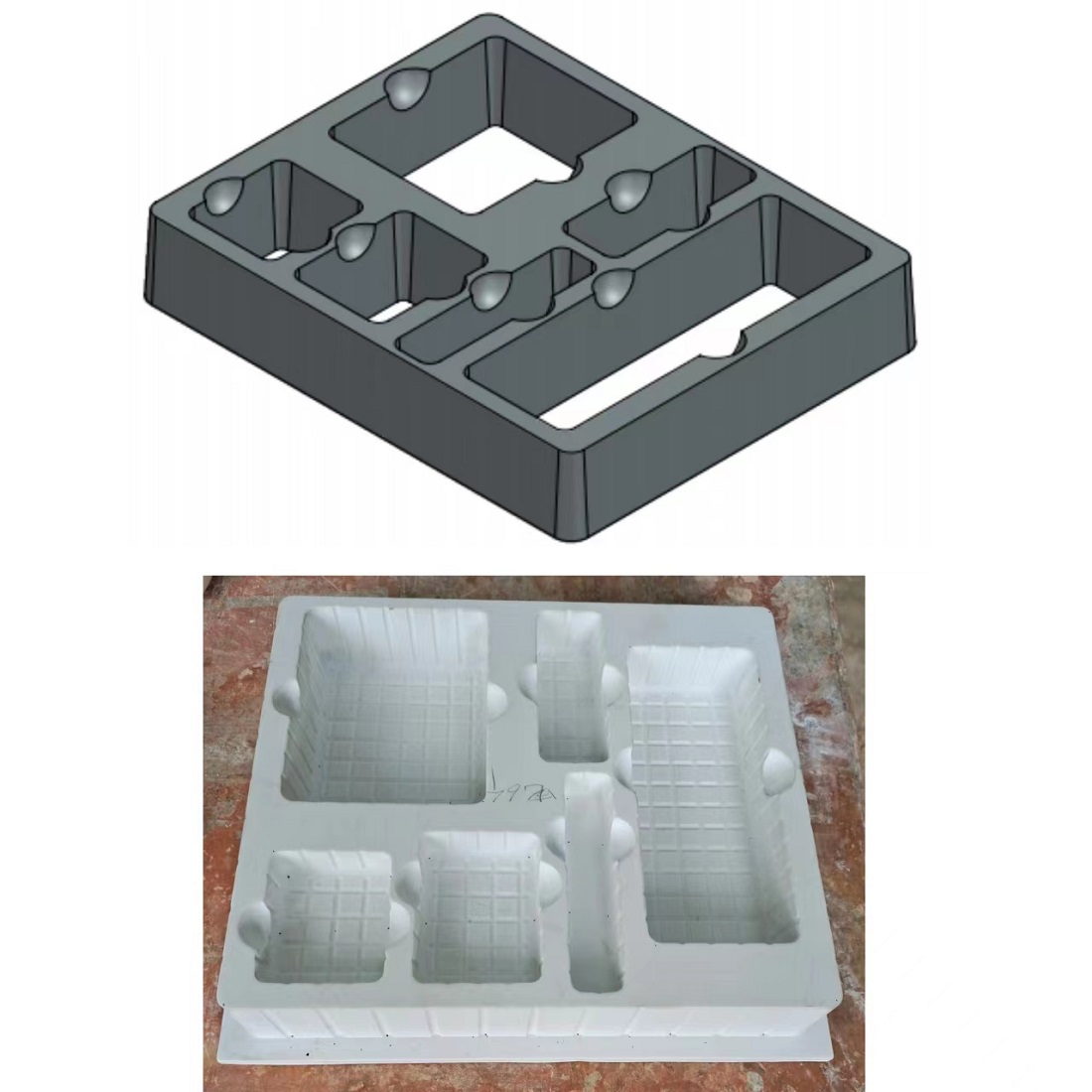

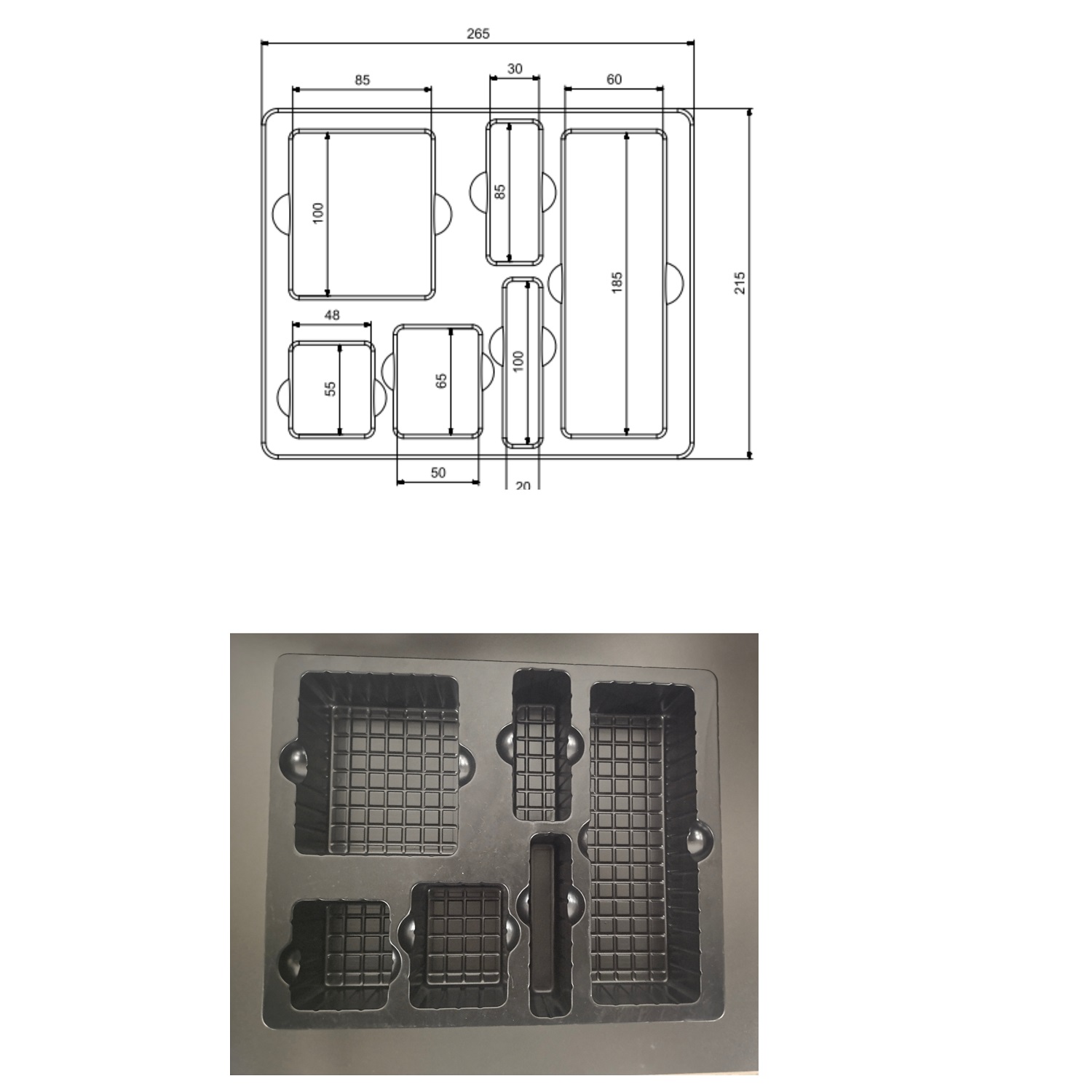

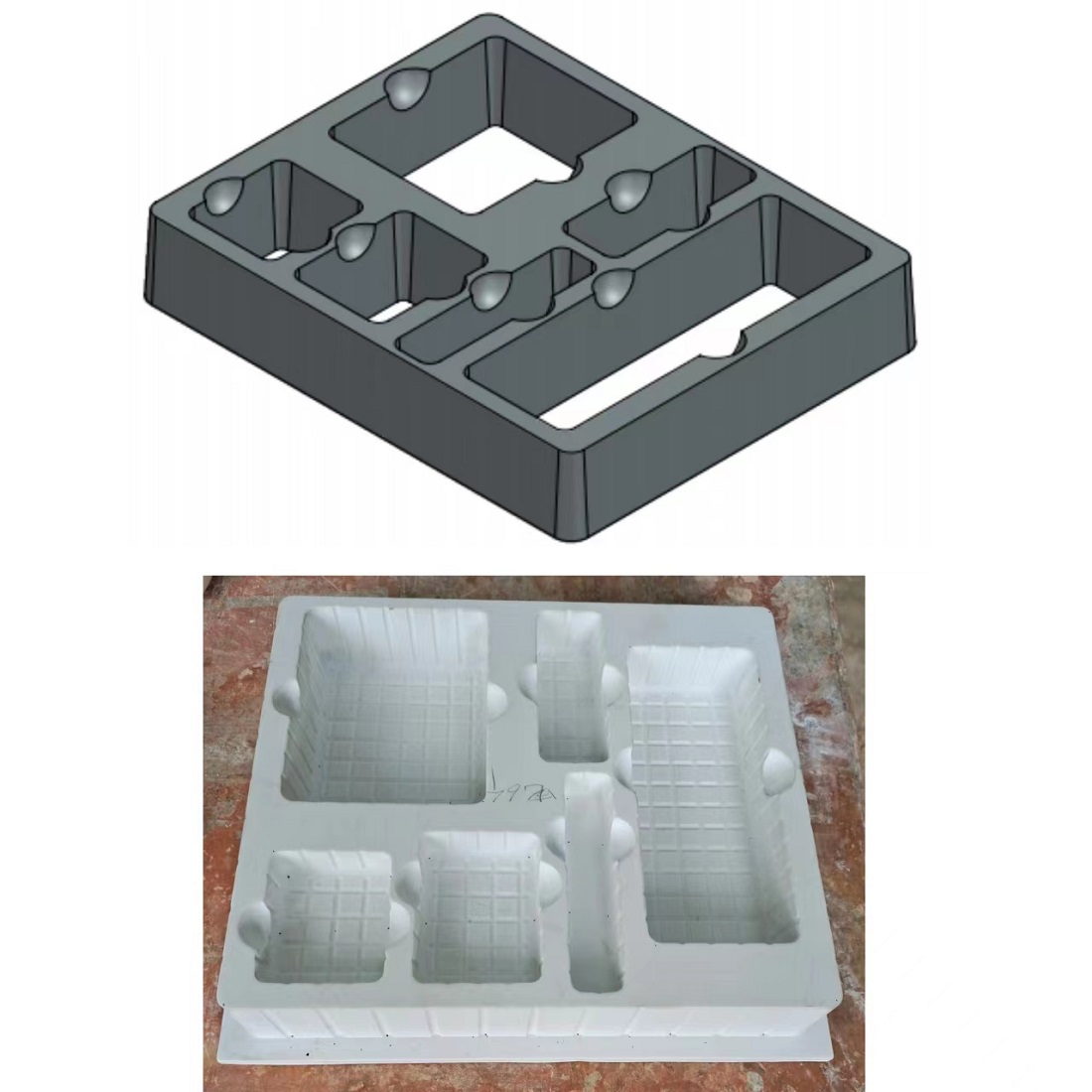

We will make mold based on product or drawing.

Third Step:

Debug the mold according to the machine and carry out production.